Welcome to the world of denim, where the fusion of tradition and innovation births the jeans we love and live in. In this blog post, we’ll pull back the curtain on Ermi Textile, a trailblazer in the jeans manufacturing arena. We’ll delve into the roots of their acclaimed reputation, revealing how they weave the very fabric of fashion-forward thinking into each thread. Join us as we explore their meticulous design process that takes a mere concept and skillfully molds it into a tangible prototype, ready for the bustling global stage. Every choice of material underpins the longevity of their garments, and we’ll uncover why durability is not just a feature but a promise. We’ll also take a glance at the sophisticated techniques that set Ermi Textile apart, while their commitment to quality control ensures that each pair of jeans isn’t just made — it’s mastered. Embark on this textile journey to discover how perfection is pieced together, one stitch at a time.Explore Ermi Textile’s journey from design to perfect jeans with a focus on material choice and cutting-edge manufacturing. Quality guaranteed.

Understanding the Foundations of Ermi Textile

Ermi Textile has established itself as a stalwart in the denim industry, known for its commitment to producing sustainable jeans that not only appeal to fashion-forward consumers but also demonstrate a profound respect for the environment. The roots of this company are deeply embedded within the principles of sustainability, setting an ethereal benchmark for other denim manufacturers in the challenging domain of ethical fashion. Ermi Textile’s consistent approach to integrating environmentally friendly techniques from the earliest design stages to the final product has heralded a new era of responsible wholesale jeans production.

Moreover, Ermi Textile distinguishes itself by not just being another name among jeans garment manufacturers; it is a pioneer relentlessly pursuing innovation while maintaining a strong connection with its traditional values. This equilibrium ensures that each pair of jeans not only exudes style and comfort but also encapsulates the brand’s commitment to its foundational ethos. By choosing the most reputable denim suppliers, Ermi Textile guarantees that each material used is a testament to durability and the brand’s unwavering pledge to quality and sustainability.

| Service | Details |

|---|---|

| Sustainable Practices | Utilization of organic materials and eco-friendly production processes. |

| Innovation in Design | Blending traditional craftsmanship with modern techniques to create unique denim products. |

| Global Supply Chain | Partnering with leading denim suppliers to ensure the best quality and ethical sourcing. |

- Adhering to high standards of quality to maintain the integrity of the final product.

- Prominent emphasis on creating sustainable jeans that cater to an ecologically conscious audience.

- Expertise as a wholesale jeans provider that supports retailers with a reliable inventory of premium denim.

The Design Process: From Concept to Prototype

The journey of crafting sustainable jeans begins with a robust design process, a trademark of Ermi Textile’s commitment to excellence in the field of denim manufacturing. At Ermi Textile, the design process is a meticulous evolution from an abstract concept to a tangible, wearable prototype, ensuring that both style and sustainability are interwoven into the fabric of each garment. Transformative ideas are translated into precise patterns and silhouettes that redefine the aesthetics of wholesale jeans, making sure that each design meets the high standards expected from leading denim manufacturers.

During the initial phases of design, the talented teams at Ermi Textile delve deep into market trends, customer preferences, and fabric innovation. This comprehensive approach underpins the work of jeans garment manufacturers who take pride in crafting apparel that’s both cutting-edge and classic. To showcase the dedication to craftsmanship, we offer an insider’s perspective through a tabulated journey from sketch to prototype:

| Phase | Description | Outcome |

|---|---|---|

| Conceptualization | Initial sketches and mood boards are created to capture the envisioned style and essence of the new denim line. | A visual representation of ideas ready for refinement. |

| Material Selection | Choosing the right denim suppliers is crucial, as the quality of denim directly impacts the durability and appeal of the jeans. | A curated selection of high-quality, sustainable denim fabrics. |

| Pattern Making | Intricate patterns are drafted, taking into account the drape, fit, and overall look of the jeans. | Accurate patterns that serve as blueprints for the prototypes. |

| Prototyping | The creation of a sample pair of jeans that embodies the initial concept while remaining functional and aesthetically pleasing. | A wearable prototype ready for testing and refinement. |

Intrinsic to Ermi Textile’s philosophy is the synergy between innovative design and environmental stewardship, which positions them at the forefront of sustainable jeans production. Through a synergistic blend of creativity and technical expertise, Ermi Textile consistently delivers prototypes that both set and follow the highest standards of the denim industry. These prototypes not only serve as the foundation for mass production but also as a testament to the skilled artisans and denim manufacturers who breathe life into every unique pair of jeans.

Material Selection: The Key to Durable Jeans

At the heart of every pair of sustainable jeans is the material from which they are crafted. The selection of premium-quality fabric not only ensures the longevity of the denim but also reinforces the commitment of denim garment manufacturers like Ermi Textile to eco-friendly practices. The industry is seeing a noticeable shift as more consumers demand garments that promise durability and minimal environmental impact, which has led to denim suppliers rigorously testing and selecting materials that meet these exacting standards.

Wholesale jeans providers are now recognizing that the key to crafting durable jeans that withstand the test of time—without compromising on style or comfort—relies heavily upon the meticulous process of material selection. As leading denim manufacturers, Ermi Textile has developed a refined process to scrutinize and choose the best possible textiles, ensuring that each pair of jeans produced is not only strong and hard-wearing but also aligns with the principles of sustainable fashion. This commitment is evident in the following table outlining the materials used:

| Material Type | Description | Sustainability Factor |

|---|---|---|

| Organic Cotton | High-quality cotton grown without harmful pesticides or synthetic fertilizers. | Reduces environmental footprint and promotes soil health. |

| Recycled Polyester | A synthetic material made from recycled PET bottles, adding strength to denim. | Helps to decrease plastic waste and reliance on petroleum-based materials. |

| Blend Fabrics | Combining natural and synthetic fibers to enhance durability and comfort. | Optimizes the use of available resources and extends the life of the garment. |

The efforts of jeans garment manufacturers to prioritize high-quality, sustainable materials have a profound impact on the industry, influencing the operational standards of denim suppliers globally. As the demand for eco-conscious apparel surges, the dedication to producing sustainable jeans serves not only as a testament to the brand’s values but also as a beacon that guides the entire fashion industry towards a more responsible future.

Cutting-Edge Manufacturing Techniques at Ermi Textile

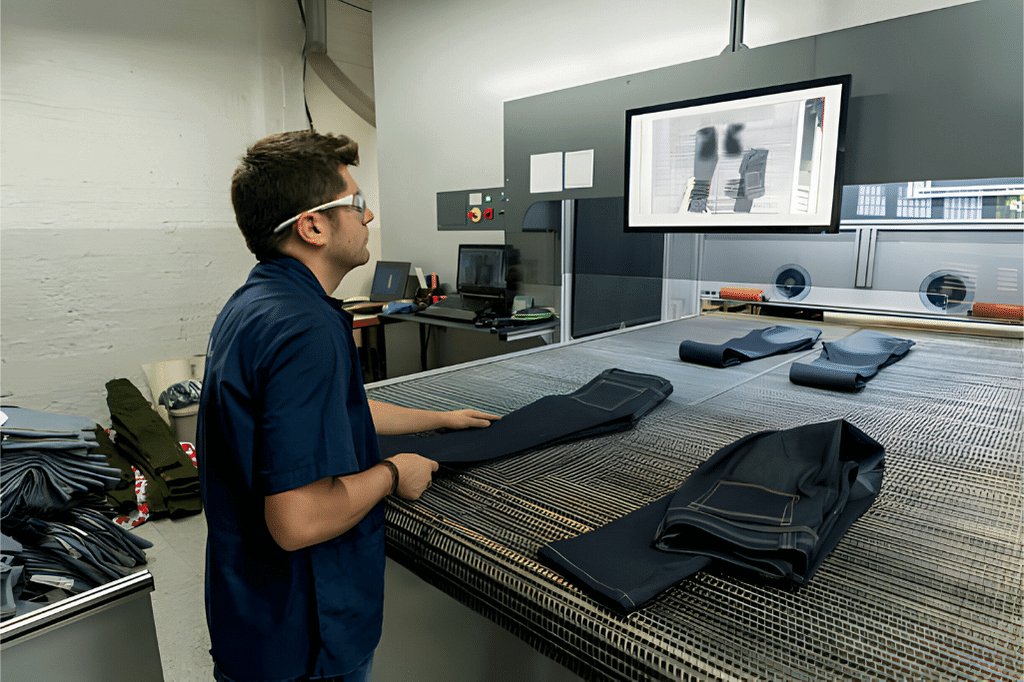

At Ermi Textile, the commitment to innovation and quality is evident through their cutting-edge manufacturing techniques, which have positioned them as a leading name among jeans garment manufacturers. By incorporating the latest technology with traditional craftsmanship, Ermi Textile successfully merges the best of both worlds to create sustainable jeans that are not only trendsetting but also durable enough to withstand the test of time.

Through relentless research and development, Ermi Textile has streamlined its denim production process, allowing for a seamless transition from design to the final product. As one of the premier denim suppliers, they understand the critical importance of keeping pace with the evolving fashion industry while prioritizing the environment. The techniques employed in their facilities reflect a balance between modern efficiency and ecological responsibility, with an end goal of providing wholesale jeans that appeal to a market increasingly conscious about sustainable choices.

- Use of laser technology for precise denim cutting, reducing fabric waste.

- Implementation of water-saving dyeing processes to minimize environmental footprint.

- Advanced automation systems that ensure consistent quality across production batches.

| Manufacturing Stage | Technique | Benefit |

|---|---|---|

| Fabric Cutting | Laser Precision | Efficiency & Reduced Waste |

| Dyeing | Eco-friendly Methods | Lower Water Usage |

| Assembly | Automated Stitching | Consistent Quality |

Quality Control: Ensuring Every Pair of Jeans is Perfect

At Ermi Textile, the commitment to excellence extends beyond the sourcing of sustainable materials and innovative designs – it is embedded in the rigorous quality control processes that ensure every pair of jeans meets the highest standards of durability and aesthetic appeal. A fundamental aspect of producing sustainable jeans is the meticulous attention to detail that is maintained throughout the manufacturing journey, from the initial cut to the final stitch.

Ermi Textile’s dedication to producing flawless garments involves several layers of inspection, implemented by skilled jeans garment manufacturers to verify that the wholesale jeans not only align with current fashion trends but also embody the resilience required for long-lasting wear. In the quest for perfection, Ermi Textile has integrated cutting-edge technologies with traditional craftsmanship, thus enabling denim manufacturers to identify and rectify any inconsistencies long before the product reaches the wholesale market.

- Every batch of fabric sourced from denim suppliers is subjected to rigorous testing to determine its suitability for high-quality jean production.

- Seams, rivets, and buttons are meticulously examined by seasoned jeans garment manufacturers to guarantee durability and function.

- Size and fit accuracy are continually monitored, reflecting the consistency and reliability that has become a hallmark of Ermi Textile’s sustainable jeans.

| Quality Control Step | Description |

|---|---|

| Fabric Inspection | Assess textile strength, colorfastness, and sustainability of materials supplied by denim suppliers. |

| Construction Analysis | Examine the assembly of the jeans, focusing on seam integrity and attachment of components by denim manufacturers. |

| Final Inspection | Conduct a thorough evaluation of the finished product to ensure each pair of jeans meets the brand’s high standards. |

In conclusion, Ermi Textile remains unwavering in its promise to deliver top-notch wholesale jeans that embody both style and substance. With rigorous quality control checks in place, they solidify their status as a leading denim manufacturer in the fashion industry, proving that when it comes to creating the perfect pair of jeans, no detail is too small to be overlooked.

Frequently Asked Questions

Complete Your Search for a Clothing Manufacturer with Ermi Textile!